FIXING CONCRETE: GEOPOLYMER CEMENT

Portland cement concrete (OPCC) is responsible for about 7% of our worldwide human carbon footprint. Partly that’s because it’s the 2nd most used material worldwide (water is the first) but it also has very high embodied energy due to the fact that portland cement is produced essentially by burning rocks!… more specifically limestone.

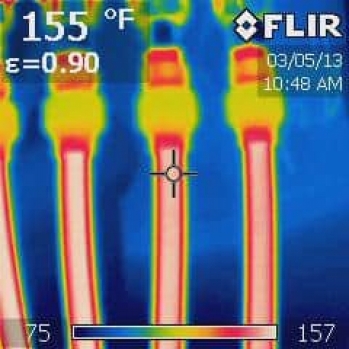

There are a number of alternatives in development and one of the most exciting is geopolymer cement concrete (GCC). Geopolymers are a class of material consisting of a mineral (geo) chain of molecules (polymer) that are linked with covalent bonds. Alumina silicate-based geopolymers when combined with certain reagents and water can produce a geopolymer cement appropriate as a binder in concrete mixes. Though the resulting GCC product has a similar range of structural and durability characteristics to OPCC, the raw materials are minimally processed and/or industrial byproducts resulting in a drastic reduction in CO2 emissions of up to 70% to 90% in comparison to OPCC, depending on which journal article you cite . It seems then that GCCs have the potential to deliver the positive high performance characteristics of conventional concrete without the negative environmental costs.

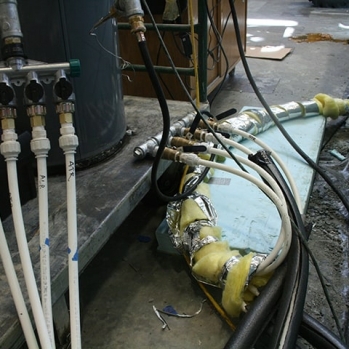

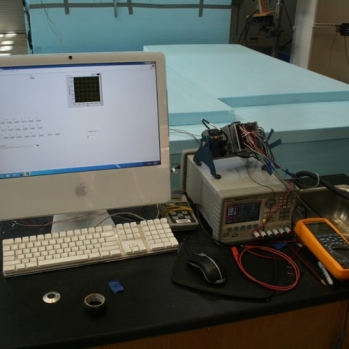

I was part of a team at UNC Charlotte studying and developing GCC mixes specifically for use in high performance building envelopes. In a partnership with Metromont, a local pre-caster, we produced the first insulated building envelope in the world using GCC as part of UNCC’s 2013 Solar Decathlon entry, proving that the technology can be produced today using existing industrial infrastructure.