MASS-PRODUCED HYGROSCOPIC ENVELOPES:THE NAUHAUS

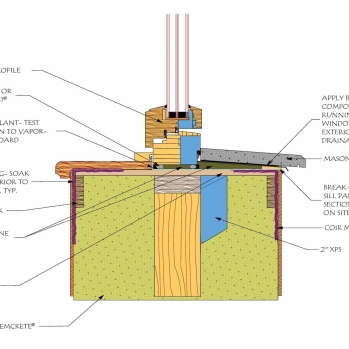

Traditional systems are great, but, let’s face it, times have changed. Our buildings have a more complex job these days as they are asked to provide a very stable interior comfort zone complete with running water and wireless internet. Also, mass production has lowered costs. If you don’t believe me go out and price a thatched roof compared to a high quality standing seam metal roof. And when it comes to financial and environmental impact, the materials themselves are only a small part of the story. It’s the operation of the building (heating, cooling, and plug loads) that is responsible for most of the resources a building uses through its life. Still, we don’t want to throw the baby out with the bathwater. Can we maintain the core wisdom of indigenous systems, which in my estimation is low-embodied energy materials and passive design tailored to microclimates, while tapping the benefits of mass-production and advanced building science? The Nauhaus Project was conceived as an attempt to do just that. The project was designed to the Passivhaus standard, probably the most rigorous building energy standard in the world which requires very careful design of an airtight thermal-bridge free envelope that allows a lower impact mechanical system and provides superior indoor environmental quality. The wall system, however, was intended to emulate many traditional systems in that it utilized mass in a hygroscopic assembly. The material chosen, Hemcrete, was made from a waste material (shiv) but engineered, packaged, and sold as a mass-produced product allowing for quality control and accurate cost estimation. Site-made materials were used when they fit the performance goals. Interior floors and mass walls are compressed earth block made on site and the interior is plastered with a variety of earthen plasters. Many innovative systems were incorporated combining simple passive technologies with high performance mechanicals. The design minimized interior square footage with extensive use of outdoor rooms creating an incredibly comfortable living space that can be heated by the body heat of ten people on the coldest day of the winter in fairly cold climate (Asheville, NC).